Discover

OUR GOAL

Developing cutting-edge

3D printing solutions

Plasmics is redefining additive manufacturing with precision, consistency, and unmatched reliability. The Plasmics platform fuses advanced hardware with intelligent software to deliver professional-grade results—every print, every time.

Feetneeds

Discover our advanced custom insole printing solutions utilizing cutting-edge, AI-powered 3D printing.

Find out more

›

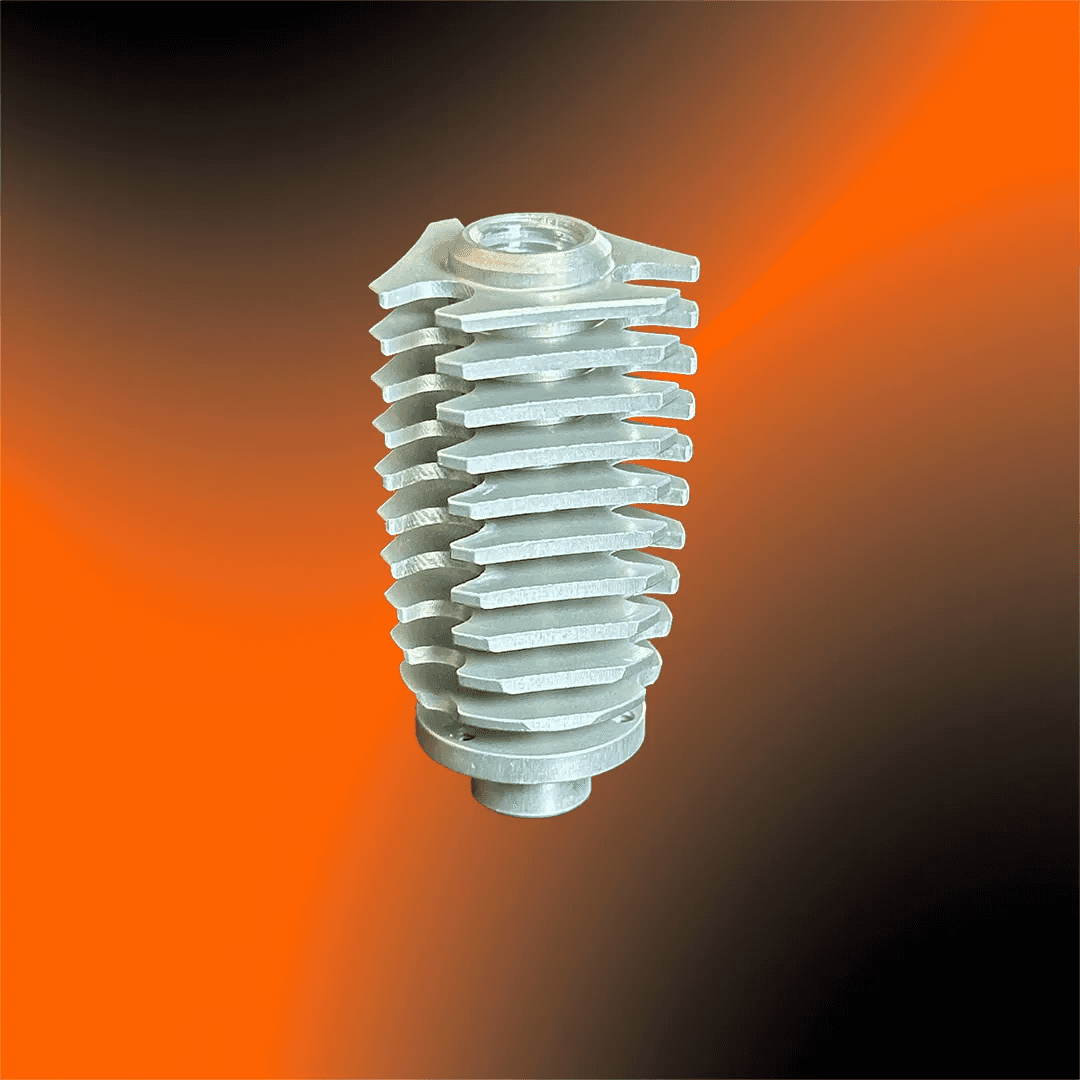

3D printed components

Plasmics system can produce professional parts anywhere—from remote workshops to global supply chains.

Contract Manufacturing

In sectors like industrial machinery, automotive, or aerospace. No need for large inventory.

Complete 3D Printing System

Plasmics systems create ideal conditions for challenging materials by combining an actively heated chamber with a dense sensor network that maintains full environmental stability. Consistent control enables reliable printing results across a wide range of advanced materials, while multi-material support unlocks composites, technical polymers, and other high-performance options.

Computer Vision & Machine Learning

The integrated computer vision system tracks every layer in real time, allowing machine learning models to identify anomalies, correct issues automatically, and maintain consistently flawless output. This continuous monitoring reduces wasted material, minimizes downtime, and optimizes overall production efficiency, ensuring the best possible results with minimal intervention.

Decentralized Production

Plasmics envisions a world where individuals and teams can produce professional-grade parts anywhere. By offering reliable, high-quality performance independent of location, the system enables a decentralized approach to manufacturing—from small, remote workshops to global supply chains—empowering creators to build precisely what they need, right where they are.

invest now

›

Sign up to the Newsletter

Join our newsletter to stay updated on product launches, events, and breakthroughs in 3D printing technology.

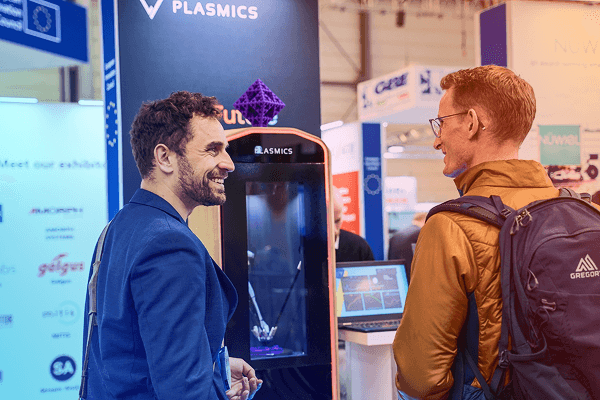

Meet Us at Upcoming Events

Discover our latest technologies and meet the Plasmics team at major industry shows and innovation conferences.

Upcoming events

OCT 24 - 25

OST 2025

Cologne, Germany